When premium tea and biscuit brands evaluate tin packaging, the question is rarely about whether tin boxes are durable enough.

What they really care about is how the packaging communicates quality at first glance—and whether that quality is still felt when the box is opened and used.

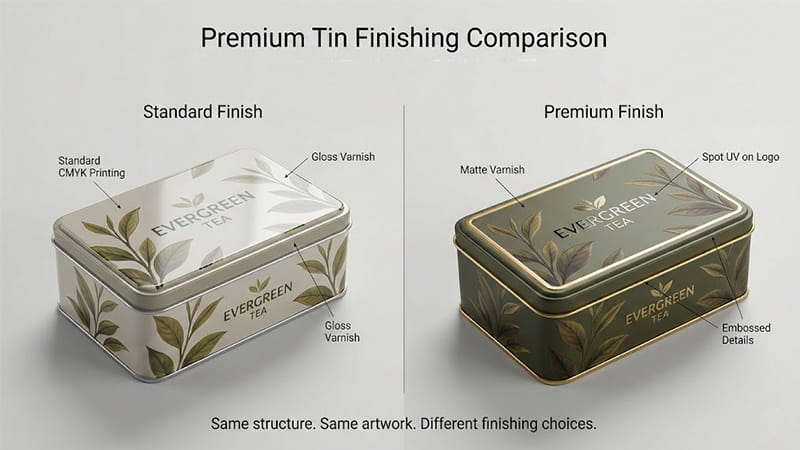

From our experience working with high-end tea producers and European biscuit brands, the difference between an ordinary tin box and a premium one is not a single “luxury feature.”

It is the combination of printing, surface finishing, and structural details, applied with restraint and purpose.

Below, we break down the practical ways premium tin packaging is achieved—and what brands should consider when upgrading beyond standard designs

For gift-oriented products like tea and biscuits, packaging is part of the product itself.

Before aroma, before taste, there is a moment of visual and tactile judgment.

A well-designed tin box should:

Feel solid when held

Reflect light in a controlled, intentional way

Communicate craftsmanship rather than decoration overload

This is where printing choices and finishing techniques begin to matter far more than many buyers initially expect.

Standard CMYK printing alone often looks flat on metal.

Premium brands usually rely on surface treatments that interact with light and touch, not just color.

Gloss varnish is widely used because it protects artwork and enhances color contrast.

However, matte varnish is increasingly favored by premium tea and biscuit brands, especially in Europe and North America.

Matte finishes:

Reduce glare under retail lighting

Feel softer and more refined in hand

Pair well with minimalist or heritage-style branding

In many projects, brands choose matte varnish for the entire tin, then add selective highlights through other techniques.

Rather than covering the whole tin with decorative effects, premium packaging uses contrast.

Common approaches include:

Spot UV applied only to logos or product names

Gold or silver foil stamping for brand marks

Minimal metallic accents instead of full metallic coverage

This restrained use of special printing makes the design feel intentional, not excessive—an important distinction for high-end positioning.

Embossed or debossed elements add a level of craftsmanship that printing alone cannot achieve.

From a production perspective:

These techniques require precise tooling

Artwork must be adjusted to avoid distortion

Depth must be controlled to prevent metal fatigue

From a branding perspective:

Texture reinforces authenticity

Raised logos or patterns subtly increase perceived value

The tin feels “designed,” not mass-produced

This is particularly effective for biscuit tins intended as seasonal gifts or collectible packaging.

Many tea brands ask whether a laser or holographic finish is possible on tin packaging.

The answer is yes—but with specific production considerations.

The holographic appearance does not come from ink.

Instead, a special film is laminated onto the tinplate before printing, allowing the printed colors to interact with the reflective surface beneath.

This technique:

Produces multi-angle color shifts

Works best with controlled color palettes

Is especially effective for limited editions or festive packaging

Laser-effect tins are visually striking, but not suitable for every brand.

They are most effective when:

The product targets younger or trend-driven consumers

The tin is used as a gift item

The brand identity supports bold visual statements

For traditional or heritage tea brands, this effect is often used sparingly—or avoided altogether in favor of more understated finishes.

While printing defines the first impression, structure defines the long-term experience.

Many premium tea tins look simple on the outside but feel noticeably different once opened.

An inner lid adds both practicality and perceived quality.

Benefits include:

Improved protection against moisture and aroma loss

A more deliberate opening experience

A visual cue that the product is carefully packaged

For loose-leaf tea, this structure is often associated with higher-end positioning, even when external designs remain minimal.

Wire-buckle tea tins are commonly seen in European specialty tea markets.

They convey:

Mechanical reliability

A sense of tradition and craftsmanship

Strong resealing performance for dry goods

While the structure is more complex than standard press-fit lids, the perceived upgrade is immediate and intuitive to consumers.

One common misconception is that premium packaging requires as many special processes as possible.

In reality, overuse often leads to the opposite effect.

From a manufacturing standpoint:

Multiple special processes increase defect risk

Certain finishes can interfere with each other

Production costs rise faster than perceived value

From a branding standpoint:

Overdecorated tins feel busy

The brand message becomes diluted

Simplicity loses its impact

In most successful premium projects, brands select one or two core enhancements and execute them precisely.

Based on real production experience, we typically recommend:

Choose one primary surface finish (matte or gloss)

Add one focal enhancement (embossing, spot UV, or foil)

Upgrade structure only where it improves real usage

Avoid stacking multiple decorative effects without a clear purpose

Premium packaging is not about showing everything that is possible—it is about showing only what matters.

High-end tin packaging does not come from a single material or technique.

It comes from consistent decisions across design, finishing, and structure, guided by how the product is meant to be perceived and used.

For tea and biscuit brands, tin boxes offer a rare advantage:

they can combine visual appeal, tactile quality, and long-term usability in a single package.

When executed thoughtfully, the tin itself becomes part of the brand story—long after the product inside is gone.